What We Clean

Eagle Services offers decades of professional experience, technical expertise and trained personnel to safely meet your industrial cleaning and/or environmental cleaning needs for all types of process industries and municipalities throughout North America.

-

WE CLEAN:

• Drains and Troughs

• Dryers

• Evaporators

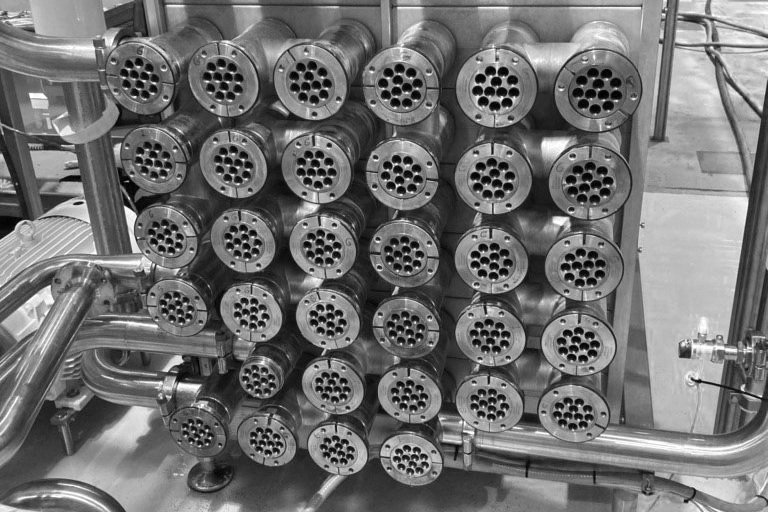

• Exchangers

• Fans

• Fin Fan Air Coolers

• Food Grade Process Equipment

• HVAC Equipment

• Pumps & Other Machinery

• Paint Booths

• Pits, Ponds, & Lagoons

• Process Piping

• Rail Cars

• Reactors

• Sewers & Drain Lines

• Silos

• Tanks & Vessels -

INDUSTRIES SERVED:

• Agribusiness

• Automotive

• Chemical Processing

• Environmental / Response Contractors

• Food Processing

• Government

• Industrial Gas

• Manufacturing

• Municipalities

• Natural Gas

• Personal Care Products

• Petroleum Refineries

• Pharmaceuticals

• Pipe Lines

• Plastics Processing

• Power Generation

• Pulp and Paper

• Rail

• Resins

• Steel Mills / Metals

• Transportation

• Water Treatment

Custom Solutions

Call on Eagle Services to evaluate your problem and recommend the solution. The Eagle Services Team holds over 60 years of industrial cleaning experience. We will meet with you one-on-one to develop an action plan, analyze job safety needs, and execute the service to get your systems back online, increase production, and cut down on maintenance costs.

Industrial Cleaning & Environmental Services

Read more about our core services:

We also provide Biohazard Decontamination, Concrete Scarification, Dry Ice Blasting, Paint Prep, Pipeline Cleaning, Pumping / Dewatering, Sewer Cleaning, Special Waste Hauling, Spill Response, Vacuum Liquid, Video Inspection, and Watercutting. Read more >

Case Studies

-

• Automated High-pressure Waterblasting for a 7000-tube Evaporator

• Automated High-pressure Waterblasting for a 3,000-tube Exchanger at a Chemical Plant

• Dry Ice for Food Processing Equipment

• Automated High-pressure Waterblasting to Clean Paint Booths

• Automated High-pressure Waterblasting and to Clean Rail Cars

• Automated High-pressure Waterblasting to Clean Chemical Plant Reactors

• Dry Ice Blast to Clean Steam Turbines

• Ultra High Pressure Water Cutting for Hydro Demolition of Coke Plant Decanters

-

-

-